hardness tester vickers|vickers hardness tester for sale : maker The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size . See more Resultado da Capturas de tela do iPhone. Conheça o App oficial do Banco BRP. Movimente sua conta corrente, faça pagamentos, transferências e consulte seu .

{plog:ftitle_list}

Resultado da Well, if you're ready to embark on this powerful journey, let Movida Escorts be your guide as we unveil the secrets to becoming a successful London .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size . See moreIt was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter . See moreWhen doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work . See moreTo convert the Vickers hardness number to SI units the hardness number in kilograms-force per square millimeter (kgf/mm ) has to be multiplied with the standard gravity, $${\displaystyle g_{0}}$$, to get the hardness in MPa (N/mm ) and furthermore divided . See more

If HV is first expressed in N/mm (MPa), or otherwise by converting from kgf/mm , then the tensile strength (in MPa) of the material can be approximated as σu ≈ HV/c , where c is a constant determined by yield strength, Poisson's ratio, work-hardening . See more

The fin attachment pins and sleeves in the Convair 580 airliner were specified by the aircraft manufacturer to be hardened to a Vickers Hardness specification of 390HV5, the '5' meaning five kiloponds. However, on the aircraft flying Partnair Flight 394 the pins were later . See more• Indentation hardness• Leeb Rebound Hardness Test• Hardness comparison• Knoop hardness test See more

• Meyers and Chawla (1999). "Section 3.8". Mechanical Behavior of Materials. Prentice Hall, Inc.• ASTM E92: Standard method for Vickers hardness of metallic materials (withdrawn and replaced by E384-10e2) See moreThe Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an optical measurement system.

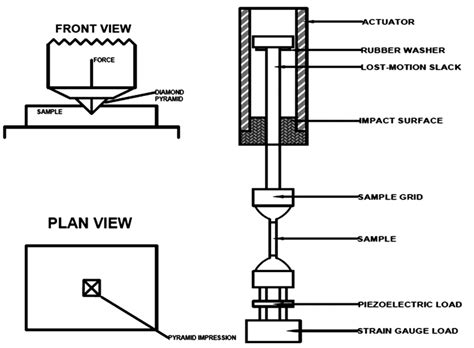

vickers hardness testing machine diagram

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO .The Vickers hardness test. Vickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load. The diagonals of the indent are measured optically in order .

This Micro Vickers hardness tester is a precise testing system suitable for hardness analysis of metallic specimens in metallography laboratories or production environments. Designed to test in Vickers (HV) and Knoop (HK) hardness scales. All Vickers hardness models in this series are supplied with an Auto Turret.

Configure your VH3000 Series Vickers-Knoop Hardness Tester and select from motorized stage sizes, vertical test capacity, optics, and load cell selections. Request a Quote Part # Description Main Unit W3111 3 objectives + 1 indenter, 0.050 - 10kgf load range, includes DiaMet workstation and 24" monitor .

Vickers hardness testing is extensively used in the metals and alloys industry to evaluate different metallic materials' hardness, strength, and durability. This instrument helps evaluate metallic components' hardness, strength, and durability, ensuring they meet the required specifications and standards. 2. Automotive and AerospaceThe Vickers hardness test spans two force ranges, “micro” (10 – 1000g) and “Macro” (1 – 100kg) Vickers, offering continuous values. Micro-Vickers testing is crucial for fine-scale hardness analysis, used in diverse applications, including evaluating surface treatments. Learn More .With Vickers, Knoop and Brinell, your test tasks are carried out in a load range between 0.25 g and 62.5 kg Depending on the hardness of the specimen to be tested and the selected method, different lenses enlarge your test indentation.. Your hardness measurements are displayed on your screen in high resolution.Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to .

LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual and automatic model configurations for Microindentation, Macro-Vickers, Multi-Vickers, Brinell or Rockwell type testing. Our automatic hardness systems, designed to maximize your productivity, increase usability, simplify reporting, and streamline analysis times.Vickers hardness testing of small areas. Equipped both with the latest optical system. ideal for measuring the dimensions of indentation images and a test-force loading device that lets you set the desired test force! The HM-200 series is ideal for quality control The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.V-Test II Vickers Hardness Tester: For hardness determination on metals and ceramics. The basic set-up includes manually positioned Z-axis on test stand, manually positioned X-axis table magnetic supporting table O 100 mm. The black and white camera has digital optics with zoom micro objective and 20 times magnification including illumination – other options of objectives .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small .The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which are measured. Vickers hardness number (VHN) can be found directly from the Vickers hardness testing machine.This micro hardness tester features a built-in CCD camera for standardized automatic length measurement. Hardness can be measured simply and accurately with easy-touse PC software. The lineup also includes fully .The FALCON 500 offers a leading technology base for manual, automatic or fully automated testing of Micro and Macro Vickers, Knoop or Brinell assignments. With a wide choices of test force configurations, answering any possible .

The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search.

Testing various materials with the Vickers Hardness Tester. The Vickers hardness tester uses the hardness test that was developed in 1924 by Smith and Sandland at Vickers Ltd as an alternative to the method that uses the Brinell hardness tester, to measure the hardness of materials.The Vickers test is often easier to use than other hardness tests, since the required .

Wilson VH1102 Wilson VH1202 Hardness Scales HV (Vickers), HK (Knoop) Turret Motorized Indentors 1 indenter positionDepending on the model, the hardness tester covers load ranges from 0.3-250 kg or 3-3,000 kg. The macro hardness tester covers optical methods and differential-depth methods for your hardness testing applications. This includes Vickers, Brinell, Knoop or Rockwell.Vickers hardness test sangat ideal untuk pengujian semua logam dan karenanya merupakan metode dengan rentang aplikasi terluas.Hardness test method menurut Vickers dijelaskan dalam standar ISO 6507 (Bahan logam – Uji kekerasan Vickers – Bagian 1: Metode uji) dan ASTM E384 (Metode Uji Standar untuk Kekerasan Mikroindentasi Bahan terhadap Vickers .

Starrett Hardness Testers indicate the hardness of a material, usually by measuring the effect on its surface of a localized penetration by a standardized rounded or pointed indenter of diamond, carbide, or hard steel. . Brinell, and Vickers testers, Starrett offers the perfect tool for any material testing application. Made with high-quality .Our hardness testers for Vickers and Knoop are the perfect choice for thin sections and smaller samples. They are unmatched in accuracy and ideal for details. READ MORE. Duramin 4. An entry-level Vickers, Knoop and Brinell hardness tester, combining manual and automatic features for optimal repeatability and easy operation.

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surfaceThe 900-391 Micro Vickers hardness tester covers the load range from 10g to 1kg. Conforming to ASTM E-384/92 vickers hardness testers standards, the 900-391 series micro vickers hardness testers will offer unmatched repeatability. This micro Vickers hardness tester can also measure Knoop hardness after installing an optional knoop indentor. For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .

Electrolytic Sensor Method service

Flex Durability Tester factory service

Anúncios de acompanhantes travestis em São Paulo (SP). P.

hardness tester vickers|vickers hardness tester for sale